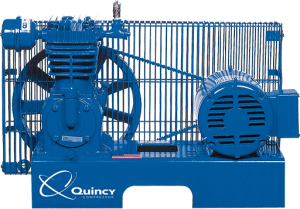

High quality rotary screw compressors such as those offered for sale by quincy compressor are designed engineered and built to provide many years of reliable service.

Quincy air compressor oil change.

Once the level drops clean out the old oil and refill.

They can assist you with selecting just the right fluid for your needs.

Rotary screw compressor maintenance rotary screw compressor maintenance.

In general manufacturers recommend changing the oil on a quarterly basis but more often with greater use.

In addition to continually producing the most innovative products in our industry a key reason for our longevity is our willingness to provide the best possible service to our customers.

When to add or change reciprocating air compressor oil will depend on factors such as the model type and operating conditions.

The problems with condensation are often especially pronounced in rotary screw air compressors where the compressor oil will sometimes spread into the air system when mixed with the condensate.

The operator should also regularly monitor the fluid level and add oil as necessary.

In doing so oil keeps the air compressor cool through many hours of heavy duty operation.

Quincy compressor has been providing reliable high quality premium performance air compressor products for nearly 100 years.

How to change the oil in a elgi air compressor.

For the oil to do its job properly you must change the oil supply on a periodic basis.

Genuine quincy air compressor parts fluid.

The combination of oil and water can lead to dirt deposits that ultimately clog the drains and pneumatic tools.

One crucial component in maintaining your air compressor is changing the oil the following instructions and video will explain how.

A quincy air compressor is designed engineered and built to provide many years of reliable service.

However a screw type air compressor is a complex machine consisting of many moving and non moving parts and components.

Changing the oil in a elgi air compressor.